- Home

- Profile

- Products

- Exporting Countries

- Vial Washing Machine in Australia

- Vial Washing Machine in Brazil

- Vial Washing Machine in USA

- Vial washing machine in Iran

- Vial washing machine in South Africa

- Enquiry

- Contact Us

Home» Bottle Washing Machines

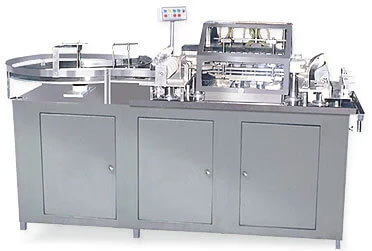

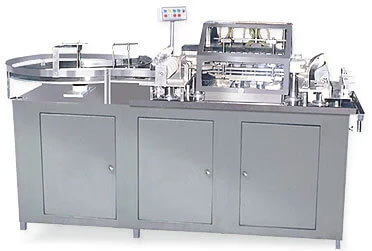

This Automatic Linear Bottle Washing machine is used for cleaning soft drinks bottle of 200ml/300ml/250ml, type it can wash upto36 bottle per minute as per speed Automatic Bottle Washing Machine is so designed that washed rough and fine wash from inside and outside and also machines take care of cleaning glass, plastic bottles without damaging any part, the machine is made up of robust and stainless hard material.

Bottle Washing Machine is with high performance, rust resistance, excellent functionality we provide customized options for washing series. Washing of bottles take place with five various washing type with 10 nozzles for optimum washing, our technicians take quality material for proper wash of bottle, all machine parts and jets are made from SS 316 tools. We are Bottle Washing Machine Manufacturer with rough stainless steel, which is highly used in several ceramic, chemical, food products industries.

We are one of the most leading Manufacturers, Suppliers and Exporters of Bottle Washing Machines Model Drbw - 150 and also exports wide range of machines. Our technicians checked it on various bases for its better output, quality component and advance technology is used for Bottle Washing Machine. Bottle Washing Machine is used for washing softdrink bottle, pharmaceuticals instruments, etc. Our offered Bottle Cleaning Machine is rigorously tested on different procedures of quality to eliminate any kind of defect as per defined international industry norms and standards.

Bottle Washing Machines are highly appreciated in the industry because of their reliability, long working life and for tremendous performance. It is manufactured using high-grade raw material, stainless steel as defined by industry rules. Automatic Linear Bottle Washing Machine gives output from 90 bottles/minute to 225 bottles/minute with eight wash cycle. Bottle washing machine model DBWT-250 is designed with rough stainless steel body, and also other parts of this machine is made from SS316 material also with higher capacity pump to wash huge container.

Vial Washing Machine is widely used by a number of industries for quick and efficient use and for washing, bleaching and drying of bottles before filling it with solution, liquids, or powders. Bottle Washing machine is manufactured by using best possible quality components and technology, has various wash stages, designs and size as per needs of our important client. We deliver Bottle Washing Solution to our customer after testing it on different basis and is constructed of stainless steel, provides robust structure for continuous operation.

| Model No | DBW – 50 | DBW – 100 | ||||

| Output | 30 to 50 bottle / Min (Depending On Bottle size) |

60 to 100 bottle / Min (Depending On Bottle size) |

||||

| Optional Accessories | 2 Pumps Pumping station , Vial inspection station, Vial loading platform | |||||

| Utilities | Fresh water 5 Ltrs/ Min DM water 10 Ltrs/ Min WFI water 5 Ltrs/ Min Air 30 CFM @ 5 Bar |

|||||

| Change Parts |

|

| ||||

| Input Specification | 30 ml (25mm) to 120 ml (55 mm dia) Net Weight : 550 kgs, Gross Weight : 950 kgs |

30 ml (25mm) to 120 ml (55 mm dia) Net Weight : 300 kgs, Gross Weight : 500 kgs | ||||

| Power Supply | Main Unit : |

Main Unit : 0.75 Hp, 440 Volt, 3 Phase, 4 Wire System, 50 Hz Optional Accessories (2 Pumps - Pumping Station ) 1.5 Hp, 440 Volt, 3 Phase, 4 Wires System , 50 Hz (Electrical Loading Platform) 0.25 Hp, 440 Volt., 3 Phase, 4 Wire System, 50 Hz |

||||

| Overall Dimension | 4178 mm (L) x 2575 mm (W) x 850 mm (H) min | 3578 mm (L) x1985 mm (W) x 850 mm (H) min | ||||

Internal /External Washes |

Washing Media |

Consumption Liters/Min. (Depending on Vial Size) |

1st Wash |

Recycled Distilled + Fresh Water |

01 To 4.8 |

2nd Wash |

Air |

--- |

3rd Wash |

D.M. Water |

01 To 4.8 |

4th Wash |

D.M. Water |

01 To 4.8 |

5th Wash |

Air |

--- |

6th Wash |

Distilled Water (WFI) |

01 To 4.8 |

| Buyer should have to provide 3 bar Pressure at the Inlets of Filtered air. | ||

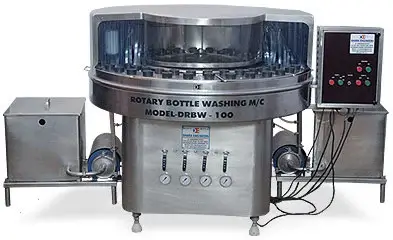

Bottle Washing Machine is with high performance, rust resistance, excellent functionality we provide customized options for washing series. Washing of bottles take place with five various washing type with 10 nozzles for optimum washing, our technicians take quality material for proper wash of bottle, all machine parts and jets are made from SS 316 tools. Machine is washed properly within time and also saves water. Rotary Glass Bottle Washing Machine is manufactured with rough stainless steel, which is highly used in several ceramic, chemical, food products industries.

| Model No | DRBW – 100 | ||||||||||||||

| Output | 60 to 100 Vial / Min (Depending On Bottle Size) | ||||||||||||||

| Input Specification |

| ||||||||||||||

| Power Supply | Main Unit : | ||||||||||||||

| Overall Dimension | 1550 mm (L) x 1700 mm (W) x 1300 mm (H) min | ||||||||||||||

| Washing Cycles & Utilities |

| ||||||||||||||

We are one of the most leading manufacturers of Bottle Washing Machines Model Drbw - 150 and also exports wide range of Automatic Tunnel Type Bottle Washing Machine in Ahmedabad. Our technicians checked it on various bases for its better output, quality component and advance technology is used for Automatic Linear Bottle Washing Machine. Bottle Washing Machine is used for washing softdrink bottle, pharmaceuticals instruments, etc. Top quality Rotary Bottle Washing Machine Exporter in India, we Dhara Engineers offered machines which are rigorously tested on different procedures of quality to eliminate any kind of defect as per defined international industry norms and standards.

| Model No | DBWT-150 | |

| Out put / Hour* | 9000 bottles | |

| No. of Pocket Across | 12 | |

| Electrical Specification** | Main Motor | 1 HP / 415 Volts / 50 Hz |

| Pump Two Nos. | 1 HP x 2 = 2 HP / 415 Volts / 50 Hz | |

| Electrical Heater | 3 Kw. | |

| Conveyor | 0.5 HP / 415 Volts / 50 Hz | |

| Tank Capacity | 80 Ltrs. S.S. 316 | |

| Wash Cycle | 3 Inner + 1 Outer + 1 Air | |

| Cycle Timing | 3.5 Second for each wash + 1.5 second for traveling. | |

| Water / Air Consumptions | 400 Ltrs. / Hr / Cycle / Pressure 2.5 Kg @ 20 CFM | |

| Machine Dimensions (In mm) | 1450 x 2500 x 1550 | |

| Case Dimensions (In mm) | 1900 x 3000 x 2000 | |

| Net Weight | 1600 Kgs | |

| Gross Weight | 2200 Kgs | |

| Change parts required | (A) Neck Dia. Bottle holding pocket. (B) Flat Container Size: Delivery chute. |

| Container Size** | Round Shape | (A) Ø 30 mm to Ø 65 mm *** (B) 58 mm to 190 mm*** (Height option for other bottle height available) (C) 20 to 55 Neck Diameter*** |

| Flat / Square | (A) 30 mm to 100 mm (Length)*** (B) 10 mm to 50 mm (Width)*** (C) 58 mm X 190 mm (Height option for other bottle height available) |

Automatic Linear Tunnel Bottle Washing Machines are highly appreciated in the industry because of their reliability, long working life and for tremendous performance. It is manufactured using high-grade raw material, stainless steel as defined by industry rules. Glass Bottle Washing Machine gives output from 90 bottles/minute to 225 bottles/minute with eight wash cycle. Bottle washing machine model DBWT-250 is designed with rough stainless steel body, and also other parts of this machine is made from SS316 material also with higher capacity pump to wash huge container.

| Model No | DBWT-250 | |

| Out put / Hour* | 12000 bottles | |

| No. of Pocket Across | 16 | |

| Electrical Specification** | Main Motor | 1 HP / 415 Volts / 50 Hz |

| Pump Two Nos. | 1 HP x 2 = 2 HP / 415 Volts / 50 Hz | |

| Electrical Heater | 3 Kw. | |

| Conveyor | 0.5 HP / 415 Volts / 50 Hz | |

| Tank Capacity | 80 Ltrs. S.S. 316 | |

| Wash Cycle | 3 Inner + 1 Outer + 1 Air | |

| Cycle Timing | 3.5 Second for each wash + 1.5 second for traveling. | |

| Water / Air Consumptions | 400 Ltrs. / Hr / Cycle / Pressure 2.5 Kg @ 20 CFM | |

| Machine Dimensions (In mm) | 1450 x 2500 x 1550 | |

| Case Dimensions (In mm) | 1900 x 3000 x 2000 | |

| Net Weight | 1600 Kgs | |

| Gross Weight | 2200 Kgs | |

| Change parts required | (A) Neck Dia. Bottle holding pocket. (B) Flat Container Size: Delivery chute. |

| Container Size** | Round Shape | (A) Ø 30 mm to Ø 65 mm *** (B) 58 mm to 190 mm*** (Height option for other bottle height available) (C) 20 to 55 Neck Diameter*** |

| Flat / Square | (A) 30 mm to 100 mm (Length)*** (B) 10 mm to 50 mm (Width)*** (C) 58 mm X 190 mm (Height option for other bottle height available) |

* Depends on bottle size.

** We can supply as per customer requirements.

*** With help of change parts.

Owned & Powered by :: #1 Vinayak InfoSoft - SEO Company Ahmedabad :: Disclaimer :: Sitemap